Laboratory of Mechanics of Technological Processes. Details

See also Laboratory general information

Main achievements

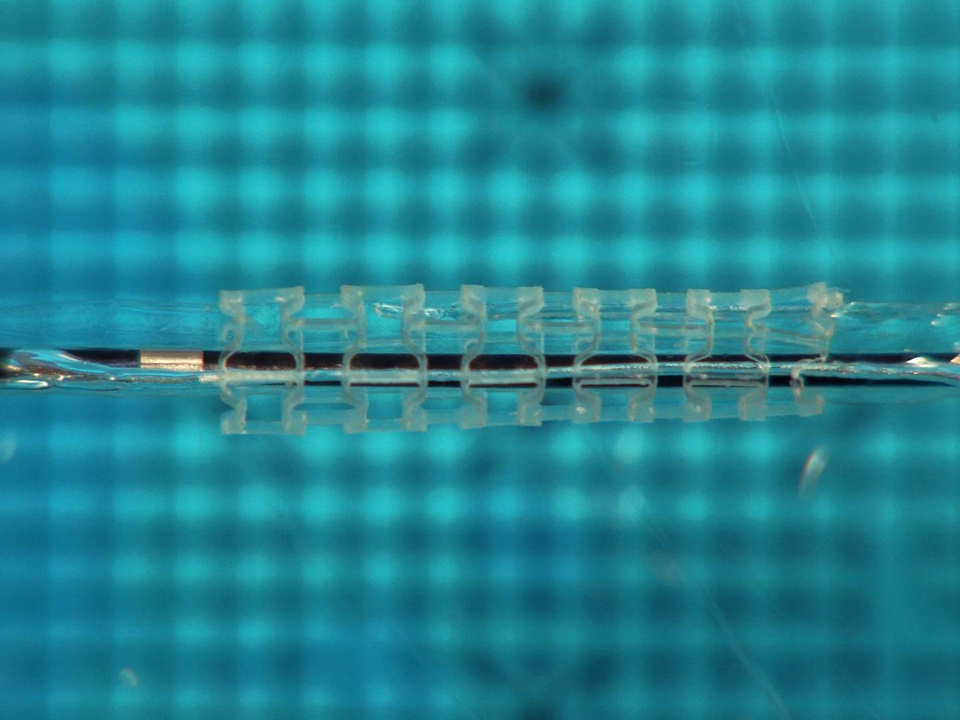

- New models have been developed that describe the mechanical properties of crystals, nano/microtubes made of them and layered composites using the theory of elasticity of an anisotropic body. The features of the mechanical behavior of materials with negative Poisson's ratio (auxetics) have been revealed. Models and designs of medical stents with auxetic properties have been developed (in cooperation with the laboratory of laser discharges).

Auxetic stent

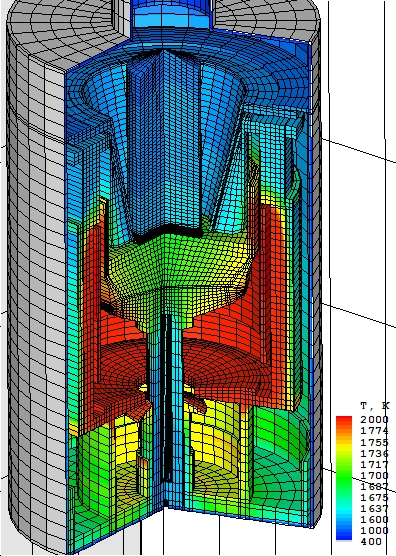

- In application to the technology for the production of very-large-scale integration circuit (VLSI) using the dislocation-free silicon single crystals of large diameters (200–300 mm), the mechanical-mathematical models, algorithms and a program code have been developed to describe heat and mass transfer processes in the melt and the grown crystal, the formation of growth defects, and also to optimize the designs of hot zones of growth equipment and the conditions for growing single crystals, providing the required content reduction and sizes of technological defects. The technological innovations have provided Czochralski process optimization of growing silicon single crystals from a melt by means of the special designs of the heat shield for the domestic heavy-charge furnace "Redmet-90M".

The optimized hot zone design of the furnace "Redmet-90M"

for growing large-diameter silicon crystals

was proposed on the basis of mathematical modeling

General information

The laboratory of mechanics of technological processes was established in January 2018. The main staff of the laboratory consisted of employees of the laboratory of Mechanics of strength and fracture of materials and structures, which was headed by corresponding member RAS R.V. Goldstein for a long time. The head of the laboratory of mechanics of technological processes was D.S. Lisovenko.

Dmitry S.

Lisovenko

Awards

- A.I. Prostomolotov – Award of Lenin Komsomol Prize in Science, 1986.

- D.S. Lisovenko, A.V. Chentsov – Medal of the Russian Academy of Sciences with awards for young scientists of the Russian Academy of Sciences, other Institutions, Organizations of Russia and for students of Institute of Higher Education of Russia, 2010.

- D.S. Lisovenko, A.V. Chentsov – Moscow Government Award for young scientists in the category of mathematics, mechanics and informatics, 2014.

Main publications

Books

- Goldstein R.V., Gorodtsov V.A. Continuum mechanics. Part 1. Fundamentals and classical fluid models. Moscow, Nauka. Fizmatlit, 2000. ISBN 5020155551 [in Russian]

- Gorodtsov V.A. Sofya Kovalevskaya, Paul Painleve and the integrability of nonlinear equations of continuous media. Moscow, Fizmatlit, 2003. ISBN 5-94052-053-7 [in Russian]

- S. Lychev, K. Koifman. Geometry of Incompatible Deformations: Differential Geometry in Continuum Mechanics. De Gruyter, 2019. xx+388 p. ISBN 978-3-11-056201-9, doi: 10.1515/9783110563214

- S. Alexandrov. Singular Solutions in Plasticity.

Springer, 2018, xi+107 p. ISBN 978-981-10-5226-2 (Print), 978-981-10-5227-9 (Online), doi: 10.1007/978-981-10-5227-9

- Polezhaev V.I., Bune A.V., Verezub N.A., Glushko G.S., Gryaznov V.L., Dubovik K.G., Nikitin S.A., Prostomolotov A.I., Fedoseev A.I., Cherkasov S.G. Mathematical modeling of convective heat and mass transfer based on the Navier-Stokes equations. Moscow, Nauka, 1987. 270 p. [in Russian]

- Buzanov O.A., Prostomolotov A.I., Verezub N.A. Hydrodynamics of the melt. Lecture course. Moscow, National University of Science and Technology "MISiS". 1997. 81 p. [in Russian]

- Polezhaev V.I., Bello M.S., Verezub N.A., Dubovik K.G., Lebedev A.P., Nikitin S.A., Pavlovsky D.S., Fedyushkin A.I. Convective processes in microgravity. Moscow, Nauka, 1991. 240 p. ISBN 5-02-006767-9 [in Russian]

Papers

- Goldstein R.V., Gorodtsov V.A., Lisovenko D.S. Mesomechanics of multiwall carbon nanotubes and nanowhiskers. Physical Mesomechanics. 2009. V. 12. No. 1-2. P. 38-53.

DOI: 10.1016/j.physme.2009.03.005

- Goldstein R.V., Gorodtsov V.A., Lisovenko D.S. Volkov M.A. Negative Poisson's ratio for cubic crystals and nano/microtubes. Physical Mesomechanics. 2014. V. 17. No. 2. P. 97-115.

DOI: 10.1134/S1029959914020027

- Goldstein R.V., Gorodtsov V.A., Lisovenko D.S. Rayleigh and Love surface waves in isotropic media with negative Poisson's ratio. Mechanics of Solids. 2014. V. 49. No. 4. P. 422-434.

DOI: 10.3103/S0025654414040074

- Goldstein R.V., Gorodtsov V.A., Lisovenko D.S. Poynting's effect of cylindrically anisotropic nano/microtubes. Physical Mesomechanics. 2016. V. 19. No. 3. P. 229-238.

DOI: 10.1134/S1029959916030012

- Gorodtsov V.A., Lisovenko D.S. Tension of thin two-layered plates of hexagonal crystals. Composite Structure. 2019. V. 209. P. 453-459.

DOI: 10.1016/j.compstruct.2018.10.063

- Prostomolotov A., Verezub N., Mezhennyi M., Resnik V. Thermal optimization of Cz bulk growth and wafer annealing for crystalline dislocation-free silicon // J. Crystal Growth. 2011. V. 318. P. 187-192.

DOI: 10.1016/j.jcrysgro.2010.11.080

- Berdnikov V.S., Prostomolotov A.I., Verezub N.A. The phenomenon of "cold plume" instability in Czochralski hydrodynamic model: Physical and numerical simulation. J. Crystal Growth. 2014. V. 401. P. 106-110.

DOI: 10.1016/j.jcrysgro.2013.12.055

- Prostomolotov A.I., Verezub N.A., Voloshin A.E., Nishinaga T. Simulation of GaSb:Te crystal growth in space experiment. Procedia IUTAM. 2017. V. 23. P. 42-51.

DOI: 10.1016/j.piutam.2017.06.004

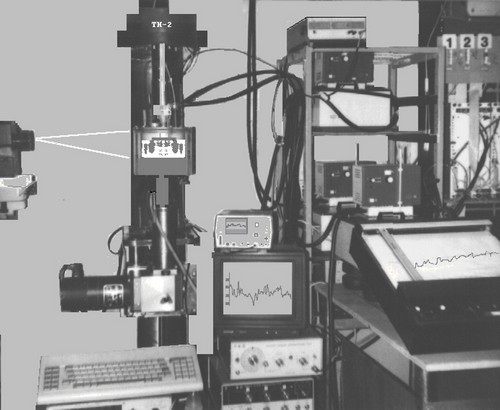

Experimental equipment

- The setup "TH-2" ("Technological Hydromechanics-2") for physical modeling of thermo-mechanical processes in application to Czochralski crystal growth has been produced in 1992–1996 by the manufacturing of IPMech RAS. This setup has high-precision, low-inertia rotation and linear displacement drives, high axial symmetry of the crystal and crucible simulators, and a reliable temperature control system for working surfaces. In the course of its application in the following years, the TH-2 setup was permanently modernized and equipped with the modern measuring and data processing facilities during IPMech RAS programs and RFBR grants.

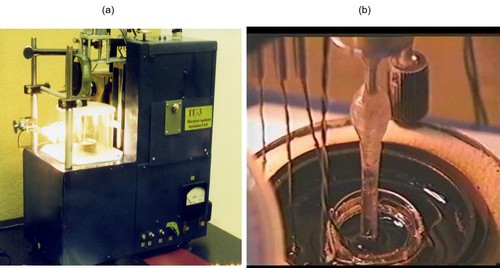

"TH-2" setup for simulation of thermo-mechanical processes during Czochralski crystal growth

- The setup "TH-3" ("Technological Hydromechanics-3") for studying the features of thermo-mechanical processes during Czochralski crystal growth has been produced in 2017–2019 in the framework of the RFBR grant 17-08-00078-a. The modeling materials with a low melting point (up to 380°C) were grown under ordinary atmospheric conditions on this "TH-3" setup. For these researches a sodium nitrate was used, the melt of which is transparent. This has been provided the possibilities of temperature measurements and also visualitions of convective flows in a melt.

Tabletop setup for Czochralski crystal growth "TH-3" (a) and the sodium nitrate crystal growth in "TH-3" (b).

|